Once the component overheated, the system becomes unstable. The thermal design in advance can improve the system's lifespan and reduce the failure rate.

The CPU is the heart of every industrial computer and is responsible for the system's overall performance. However, it is also the primary source of heat generation when it operates at high frequency. The electricity flows through the resistance of various hardware components and starts heating the motherboard. Once the component overheated, the system becomes unstable and malfunctions or can even be damaged. As a result, the lifespan of the components is reduced. Hence, an effective heat dissipation mechanism is vital in the system's thermal design, especially in the early stages. Early development is the time when thermal management experts get involved.

One of the best ways to resolve system failure due to temperature is to do a thermal simulation in the initial design stage. DFI's dedicated thermal simulation tools and software enable engineers to perform thermomechanical and heat transfer analyses. Simulating the stress response to thermal loads and understanding the failure is essential. The earlier the thermal failure can be detected, the less effort and cost of re-designing thermal management will be. DFI emphasizes thermal simulation early in the system design and provides cost-effective solutions to its partners and customers.

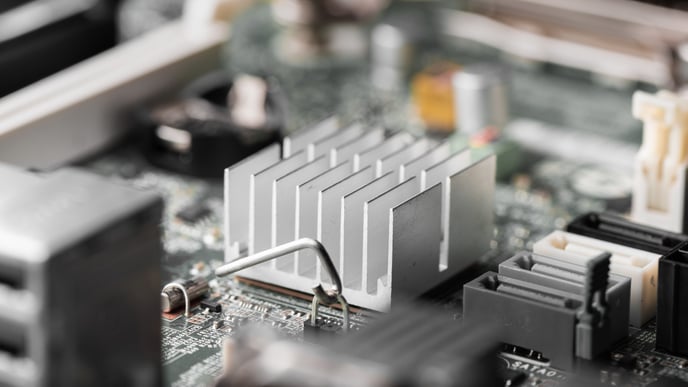

When embedded system and product design is moving towards miniaturization, cooling the parts effectively in the limited space of SBC is getting more attention, especially for the demand for passive heat dissipation like a fanless heatsink with a longer lifespan than a fan cooler.

DFI's thermal management designs concentrate on optimizing chassis structure to improve airflow. The following design methods help to ensure delivery of the best-in-class cooling performance.

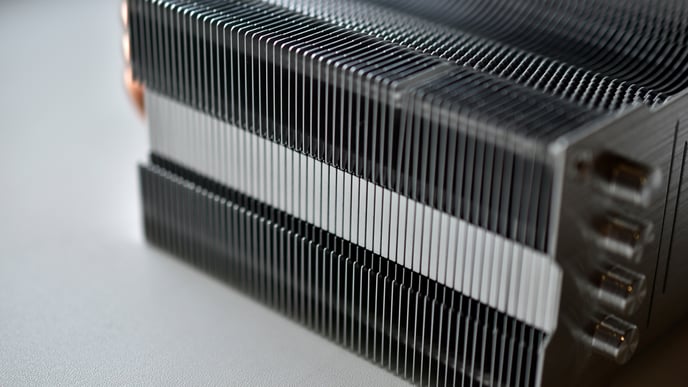

- Ensuring heat uniformity (by adding a copper platform or heat pipe) to increase heat conduction

- Use the fin spacing in the heat sinks to increase heat convection

- Increase heat radiation using emissivity on the heat sink's surface

- Deploy a "rough" surface to increase the cooling area

- Use a surface coating (such as Graphene) to improve the heat conduction/radiation

Another tool used for thermal management includes an airflow calibrator. This method has proven to be a great way to find potential temperature failures. With this tool, the designer can perform a thermal simulation to observe the heat distribution and airflow at the beginning of the heatsink design and thus construct a feasible heatsink. In addition, the tool helps ensure that the air flows in the most desired direction. For example, you want the hottest components near the airflow exit to push hot air out of the system and not pass over the more sensitive components.

Various types of heat sinks are available to a board designer, from standard to custom. They can be flat for more airflow, fins of any length, width, or shape, and they can be constructed of different materials to hit the right form factors and budgets.

DFI has a dedicated R&D team in thermal management design and provides professional advice and cost-effective solutions through various technologies, such as thermal simulation and the mechanical design of the heatsink and chassis based on thermodynamics and heat transfer. A proper thermal design in advance can significantly improve the system's lifespan and reduce the hardware failure rate.

Besides the professional thermal design skills, DFI also considers the costs of design and production process for our customers. DFI can further provide professional advice on reducing the overall costs of a thermal solution by thermal types (such as chassis, heatsink, fan…), heatsink design, and materials to help customers achieve more cost-effective solutions.

DFI offers full support to provide exclusive design, production, warranty, repairs, and life cycle management services. To make the project as easy as possible for you, DFI also works closely with customers to understand their requirements and offer real-time technical support as the solution is developed to reduce design effort and cost.

-1.png?height=120&name=DFI%20LOGO_RGB(%E9%80%8F%E6%98%8E%E5%BA%95)-1.png)